Dresser Solutions for the Utility Industries

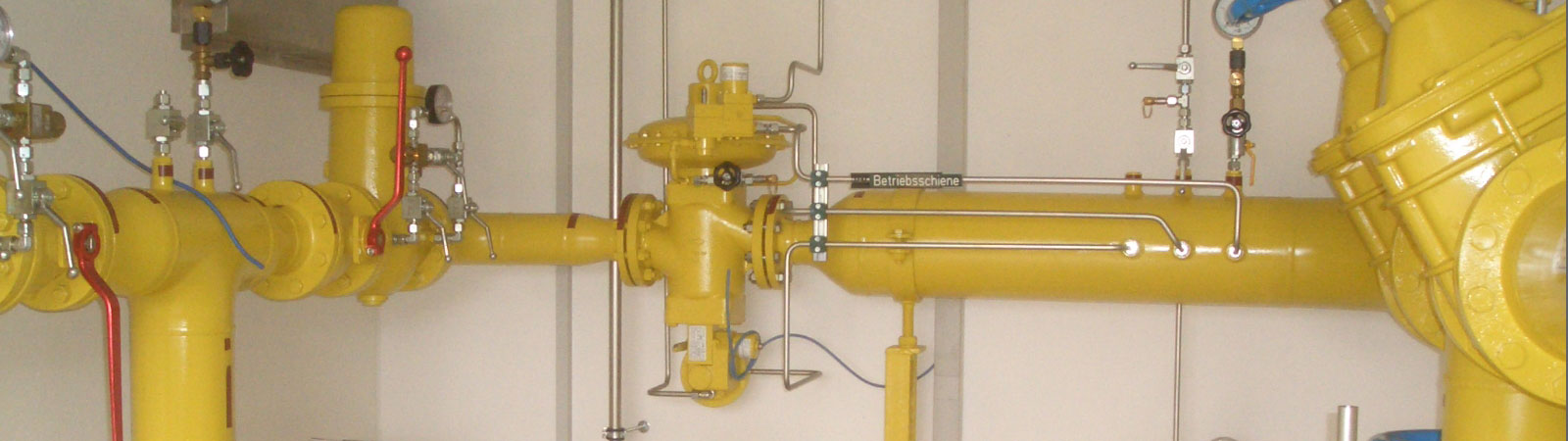

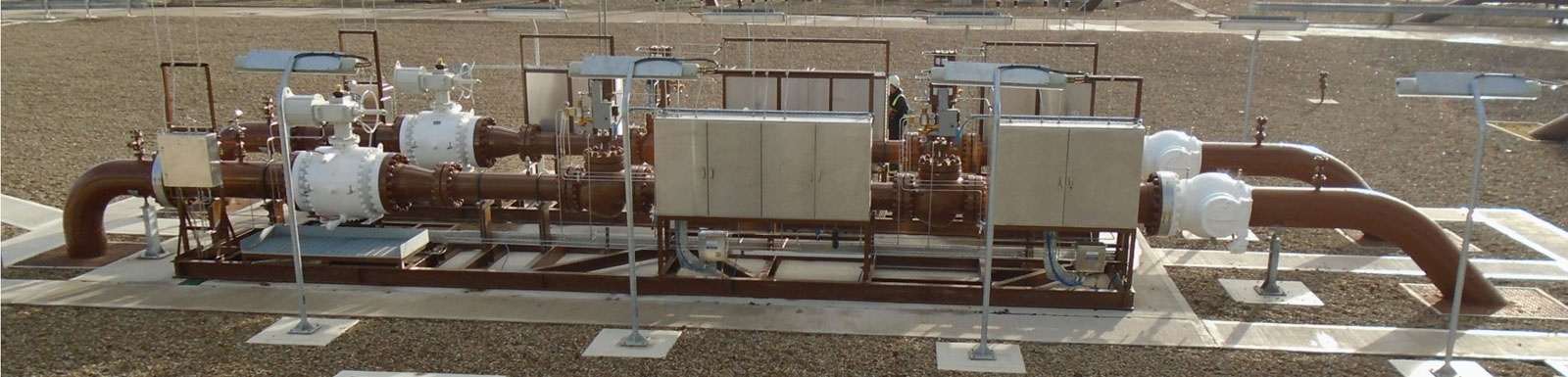

Dresser Utility Solutions is a leading provider of metering, electronics, instrumentation, flow control, distribution repair products, and over pressure protection devices to utility and industrial markets. For more than a century, Dresser Utility Solutions has been a leading worldwide manufacturer and marketer of highly engineered products for critical infrastructure in the global utility and industrial sectors. Dresser Utility Solutions core business has been serving gas utilities and going forward will focus on serving the broader Utility sector, particularly in the water and wastewater treatment customer segments. The aging gas and water utility asset base and heightened focus on ESG necessitate innovative solutions and products, which Dresser Utility Solutions is uniquely positioned to provide.

Headquartered in Houston, Texas, Dresser Utility Solutions has a comprehensive global presence, with approximately 750 employees and a sales presence in more than 100 countries worldwide.

WATER & WASTEWATER EXPANSION

Total Piping Solutions Joins Dresser Utility Solutions Family as Part of Dresser Pipeline Solutions: Dresser Utility Solutions’ acquisition of Total Piping Solutions (TPS) expands our product offerings in the water and wastewater sector to better fulfill the market demand for innovative water and wastewater applications. Additionally, this move expands Dresser Pipeline Solutions’ distribution network to further enhance. >> LEARN MORE

MARKETS WE SERVE

Natural Gas Utilities | Water/Wastewater | Industrial | Aerospace | Midstream & Production | Marine | Agriculture

Featured Videos

Latest News

- Harnessing Employee-led Emergency Response TeamsWell-implemented in-house emergency response teams can add tremendous value in an organization and make positive impacts in the wider community. Utilities are… View Article

- Utilities Business Review Article Features Dresser Utility SolutionsRead the Article on Next-Gen Solutions for Gas Utilities Dresser Utility Solutions President and CEO David Evans and Executive Vice President and… View Article

- Dresser Utility Solutions Acquires Total Piping Solutions, Expands Product Offerings in Water and Wastewater MarketsDresser Utility Solutions, a leading provider of metering, electronics, instrumentation, flow control, distribution repair products, and over pressure protection devices to utility… View Article